{Steel material}Cr12MOU,SKD11,SKH-9,DC53

{Product material}:SUS304,SPCC and so on

{Scope of application}:Automotive

{Die types}:Single process

{Mould Life}:50~100 shots

{Tolerances}:0.02mm

{Processing Date}:35~45 days

{Spare parts}:PUNCH ,MISUMI and so on

{Equipment}:400T Punch

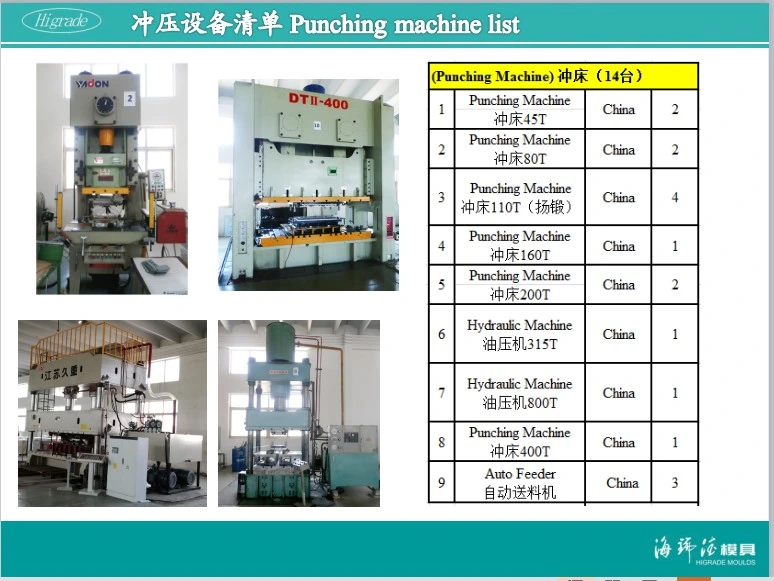

{Produce equipment}:315T Hydraulic machine/press,400T\200T\160T Punch (With the belt feeding machine),110T,80T,40T Punch equipment ,Can meet the need of mass production and testing.

{Service content}:Designing and manufacturing for metal mould and products.

{Main customers}:Haier, Hisense, Midea, Siemens, Sanyo, Electrolux, Toyota, KIA, Foton, SGMW, SKYWORTH etc.

{Main export markets}:Japan, Korea, Thailand, Russia, Germany, Britain, Norway, Italy, Spain, Turkey; America, Brazil, Argentina;South Africa Egypt; Iran, Pakistan, India etc..

{Mold paint}: Painting color depends on customer requirements

(Packaging: wooden case)

| Fitter | Quality testing |

| First die by the fitter for a thorough inspection of the mold as follows: | Die size (I* W * H) |

| Die accessories are complete | If the mold specification matching and customer equipment(height, the size of a mould, mould position) |

| Ensure the mold factory 100% acceptance (including:assembly, test mode etc.) | There is no die shank (reasonable) |

| According to the customer request is equipped with the factory. | Die code is complete (item, process name) |

| Die appearance: template logo are complete; the surfacerust are clean, then coated with anti rust oil, wooden packing. | Whether to need to mold brand |

| With mold factory data | On the,In the lower limit of a column is complete, paint color and reasonable |

| Mold inserts, punch is complete | |

| Screw dismounting have wear / screw holes are offset | |

| The die structure is reasonable / mould factory data is complete |