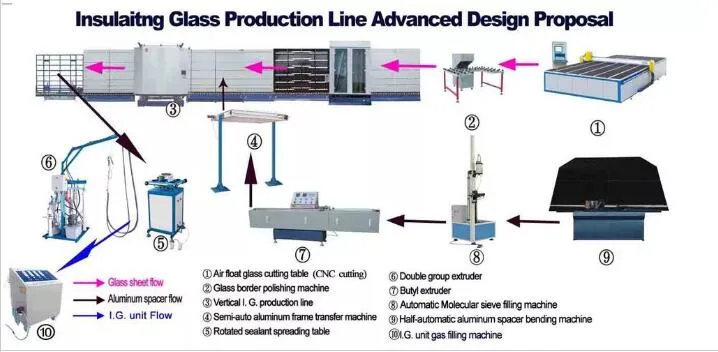

Insulating Glass Production Line/ Double Glazing Glass Machine (DGU)

Driven Mechanism

vertical roller press insulating glass production line ottom rollers from inlet conveyor till outlet conveyor are all steadily driven electrically by reliable motors with infinite gearbox with the aid of clutches. Each section could be individually driven when clutches release. Top quality parts and components guarantee consistent movement of all rollers.

Control:

This free stand alone cabinet is used to control all motors and conveyor speed, etc. With a PLC system, all operations are accessed from this control panel. Software and logic are design to assembly double glazing. Optional triple or multiple glazing is on request.

| Production feature: |

1. Double Glazed glass machine with high automatic level is fully controlled by PLC system,the operation is easy and humanized

2. Touch screen operation interface.It is easy to transfer between automation and hand-operation

3. Self diagnosis system brings much high convenience to the user

4. Automatically distinguish the film of LOW-E and coated glass

5. Double Glazed glass machine washing part is completely made of stainless steel, tempered glass door makes the operation inside clearly monitored, Signal switch on the top of the door avoid possible injure to the operater

6. Energy saving and interrupted system for the washing machine

7.Unique water nozzle design makes the maintenance easy and fast

8.Heating system for the water and blowing air. Start it when the ambient temperature no more than 7 degree

9.Automatic control 8 brushers for Glass

10. Double Glazed glass machine There is special system for Producing triple insulating glass

11. Having system for wrong operation and automatically wait the second glass following.

12. Automatic assembly inside the press machine

13.High class casting and processing of spare parts assure good stability of the line

14.The key connections use expanded joint in stead of common union.This guarantee high adjustment precision and conveying reliability

Functions characteristics:

Shape glass Low-e insulating glass production line

Automatic control for Low-e glass (6-brush treatment for LOW-E)

Automatic adjust function for pressing with hydraulic compression

Titling table with hydraulic pressure

Monitor using system temperature/speed/production volume

Mechanical trouble cheek

Whole line control function with 1 monitor

| Max working size | 2500*3500mm |

Max working size | 300*500mm |

Single Glass Thickness | 3-25mm |

Max IGU thickness | 50mm |

Washing speed | 0-8m/min |

Conveyor speed | 45m/min |

Double Glazed glass machine Cycle | 30-40 seconds(900*1200mm) |

Brusher | 3 pairs |

Brusher Diameter | Rough: 0.1mm, Fine: 0.06mm |

Electricity power | 3P 380V/50HZ or 3P 220V/60HZ |

Dimension | 17800*2500*3600mm |

Water | 0.5 ton per day |

Air Exhaust volume | 0.8m3/min |

Air pressure | 1.0Mpa |

2. Other Specification:

| Model | Max glass size |

| LBZ2200 Full-automatic Insulating Glass Production Line | 2200*3000mm |

| LBZ2000 Full-automatic Insulating Glass Production Line | 2000*3000mm |

| LBZ1800 Full-automatic Insulating Glass Production Line | 1800*2500mm |

| LBZ1600 Full-automatic Insulating Glass Production Line | 1600*2000mm |

| LBZ2500 Full-automatic Insulating Glass Production Line | 2500*3500mm |

3. Payment: Telex Transfer (T/T), 30% be paid after confirming the order and the rest 70% is effected while delivering the goods.

Package: Each PC in wooden cases.

Port of Loading: Qingdao, China

Delivery Time: During 20 days after we receive your first payment.

4. Contact information:

Ceci Liu

+ 86 15098968538