Automatic Glass Bottle Washing Filling Capping Machine For Liquid Filling

Product Application

This filling machine is used in production no-gas and gas containing beverages of PET bottle or glass bottle ,such as mineral water,pure water, coca cola , spirit drinks etc.

The whole machine designing is reasonable , the appearance is beautiful and the maintenance is convenient , it adopts bottle handing technology to make changing bottle more convenient ,faster and easier ,the machine adopts PLC control ,touch screen and no-bottle ,no-cap system The key electric elements are from famous international brand

This machine integrated three function: 1. Rinse the empty bottle, 2. filling the rinsed bottles, 3. capping the filled bottles

This washing filling capping machine is automatic washing filling capping three in one machine. It's of many advantages, such as compact structure, perfect control system and easy to be operated. Advanced touch screen and PLC control system makes man-machine communication true.

| The all parts of RELIABLE glass bottle filling machine | ||

| No | Product Name | Remark |

| 1 | Flat conveyor with one motor | 2M For Free |

| 2 | 3 in 1 main machine | Washing Filling Capping |

| 3 | Flat conveyor with one motor | 2M For Free |

| 4 | Cap loader | Full Automatic (High configuration) |

| 5 | Light checker | Free |

Technical Parameters

| Model | CGFD-G12126 | CGFD-G18186 | CGFD-G24248 | CGFD-G323210 |

| The number of Washing, Filling, Capping | 12-12-6 | 18-18-6 | 24-24-8 | 32-32-8 |

| Producing capacity; The number of bottle(600ml)/hour | 2000-4000 | 5000-7000 | 8000-12000 | 12000-15000 |

| Applicable bottle specifications (mm) | φ=50-108 H=170-340 330ml-2.25L | |||

| Pressure (kg/cm2) | 2~3 | |||

| Motor power (kw) | Main motor 1.5kw | Main motor 2.2kw | Main motor 3kw | Main motor 4kw |

| Outside vacuum pump power (kw) | 0.75 | 1.1 | 1.5 | 2.2 |

| Overall dimension (mm) (LxWxH) | 2100x1400x2500 | 2460x1720x2650 | 3100x2100x2650 | 3500x2500x2650 |

| Weight(kg) | 2500 | 3500 | 4200 | 5500 |

| Detailed Picture Show |

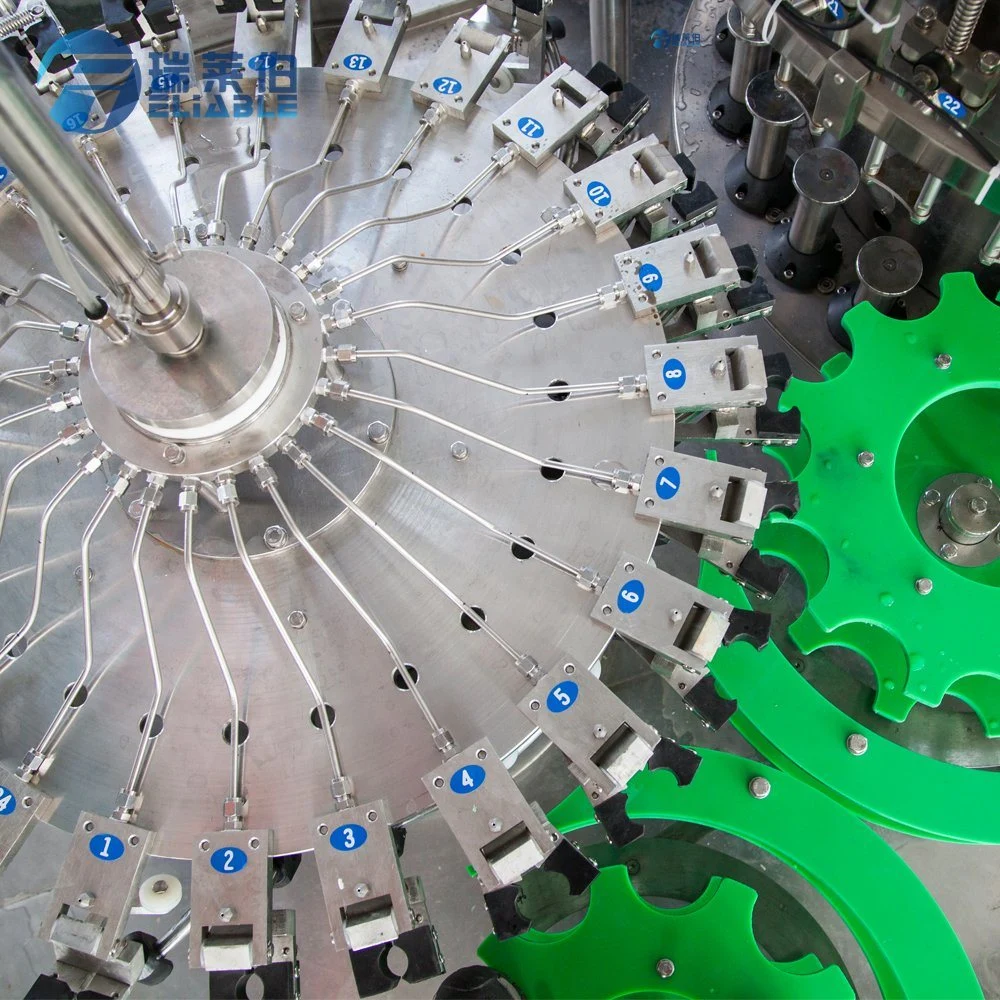

| Washing Station Washing part in the washing filling capping machine is mainly composed of washing pump, bottle clamps, water distributor, up turn-plate, guide rail, protection cover, spraying device, defrosting tray, rinse water take and rinse water refluxing tank. |

| Filling Station Filling part in the washing filling capping machine is mainly composed of filling barrel, filling valves (normal temperature and normal pressure filling), filling pump, bottle hanging device / bottle pedestals, elevating device, liquid indicator, pressure gauge, vacuum pump, etc. |  |

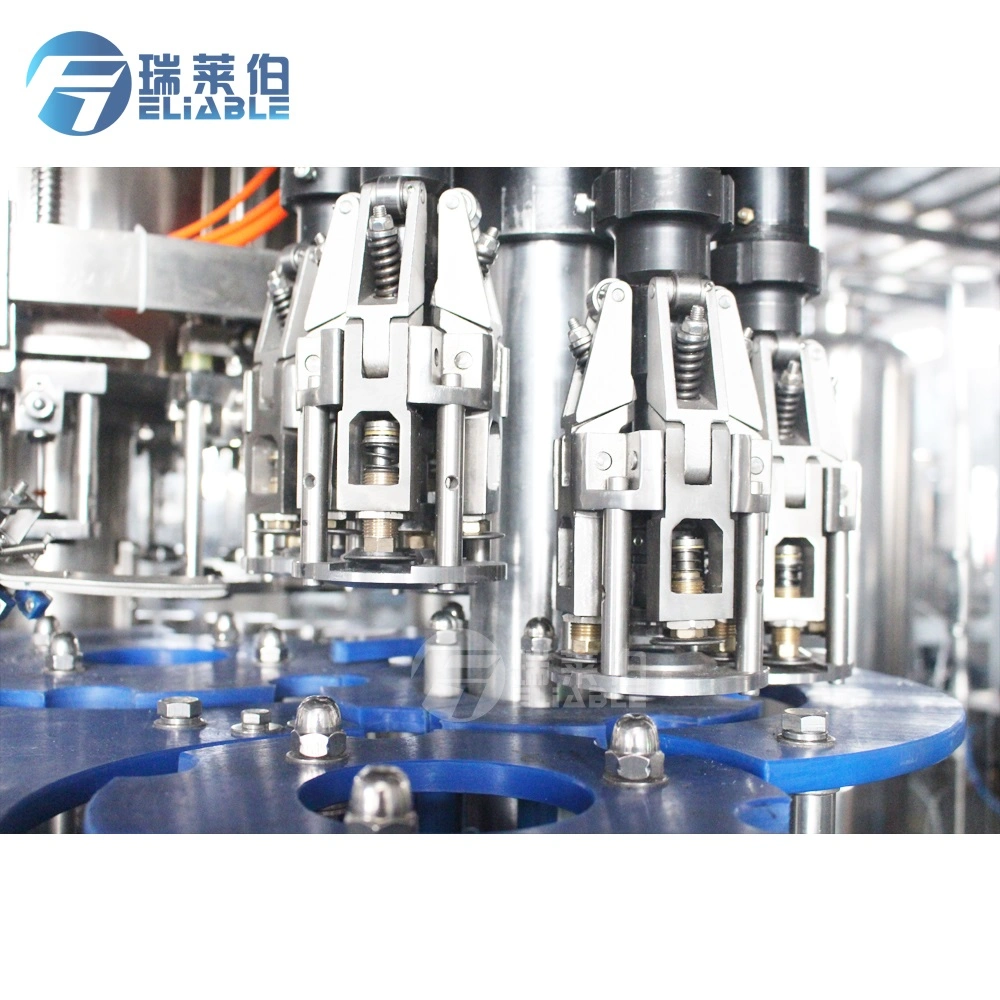

| Capper Station Capping part in this washing filling capping machine is mainly composed of capping heads, cap loader (separated), cap drop rail, pressure regular, cylinder and also we need an air compressor as the auxiliary external equipment | |

|  |

| Crown Cap | Alumium Cap |

Bottle Conveyor

It is steady to convey the bottles. The conveyor is controlled by the bottle belts and main machine or the equipment up and down to make the bottle no falling, no stuck and no stocking. The products filled by the filling machine at this time will be stored by the buffering platform. After the tags have been changed, the labeling machine will produce the bottle stored on the buffering platform at the high speed and then it will be recovered to the normal speed.

Auto Cap Loader

The caps in the tank fall into the air by the function of the vibration motor and then pass though the air conveyor of the cap to the cap sorter. It can change the size of the tank inlet by the flashboard; this can adjust the speed of cap falling.

Why Choose Us?

| Fast delivery time | 30 days after receiving the payment and sample bottles in advance |

| Long time guarantee | 1 years guarantee |

| Control cabinet voltage | 220V/380V 50Hz or by order |

| Solid packing | Wooden case packing |

| Instruction with multi-languages | Instructions in English, Russian or French |

| High quality main parts | Stainless steels 304 and imported electric components |

| Door to door service | Technical personal for installation and training on site and free translator on site |

| Authentic certification | CE, SGS, ISO |

| Online professional reply | Responding in 24 hours to the customers' questions |

| Big range for filling | Filling machines from 2,000-22,000 bottles per hour |

| Low energy cost | Ecologic design with low cost of energy |

| High flexibility | The filling machines can be designed according to the customer's special requirement |

| Free Services | Bottle Designing Label Desigining Professional Technical Supportance Layout Designing etc.. |

We are specialized in beverage machine. We offer varies stand-alone devices(such as Processing System, Water Treatment System, Blow Moulding System, Filling System, UVT System, Secondary Packing System). Our company has years of design experience and numbers of proprietary technologies. Most of elements employ foreign advanced products. Long warranty time and good service will make you satisfied. Regular processing reports will tell you the production process roundly. We are Reliable-Machine Co.,Ltd. We can be your reliable supplier.

What service Reliable Machinery Co.,Ltd can offer you ?

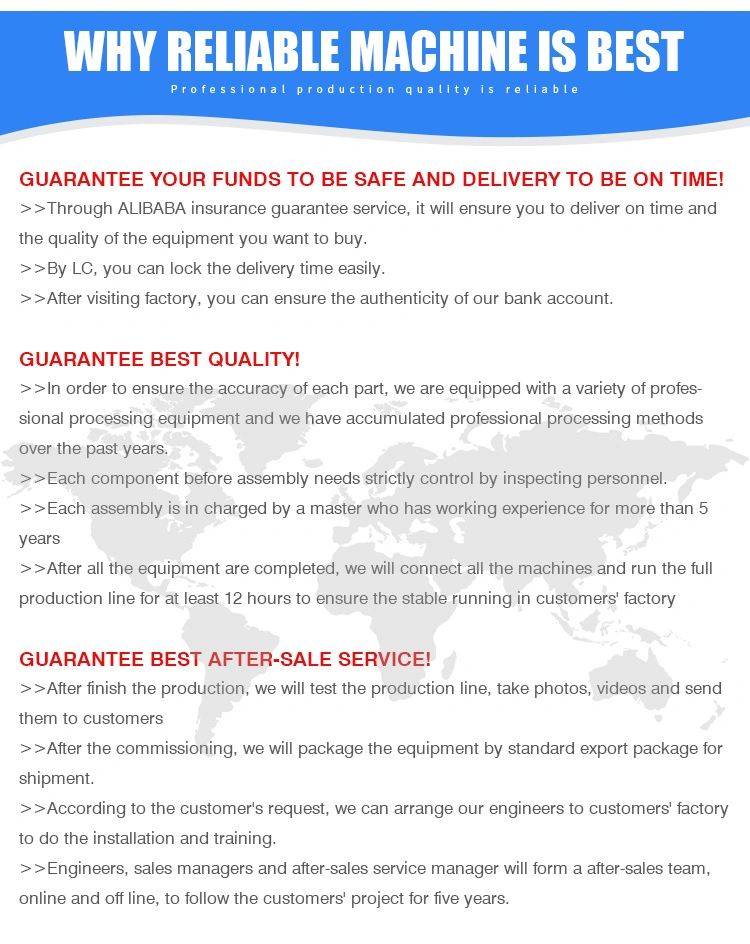

Inspections

We have our own QC department in our factory to make sure that all our products are in very good quality before ship out to our customers.

The Sample Service

1.We can send you the video of the running machine.

2.You are welcome to come to visit our company,and see the machine running in our factory,we can pick you up from the station near our city.

3.If we get the permission of the customer who has brought the machines from us ,we can tell you their contact information,you can go to visit their factory.

Customized Service

1.We can design the machines according your requirements(material,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

2. We can offer some professional suggestion when you begin this project, such as draw the factory layout for you,analyze the source water report.

After-Sales Service

1.We will provide the bill of load on time to make sure you can get the machine quickly.

2.When you finish the Preparation conditions ,our engineer will go to your factory to install the machine ,and give you the operating manual ,and train your employee until they can operate the machine well.

3.We ask feedback from our customer and offer help when the production line have been used for some time!

4.We provide one year warranty with spare parts free.

RELIABLE supply and manufacture the followings machines for you

1) Water treatment equipment----RO purified equipment, UF purified equipment, Sand filter, Carbon filter, Water softner, Sea Water treatment.

2) Filling Machine----3 in 1 Washing filling capping---for your water,cabonated drink, juice,wine,vinegar, milk,tea and so on.

----150 to 2000ml bottle, 3.5-10L,11- 20L bottle (3-6gallon bottle)

----PET bottle, Glass bottle, PP bottle and Can

----Screw cap, Aluminum cap, Grown cap and three (four) twist caps etc.

3) Labeling Machine----Stick label, Shrink sleeve label, Hot melt Opp labels. Wet gule label

4) Printer , Manual code printer , Inkjet printer , Laser printer

5) Packing Machine----Shrink film, Cartons packing machine

6) Bottle Blowing Machine--- for making plastic bottle

7) Injection Molding Machine---for your cap and proform.

8) Subsidiary products for drink production---Bottle Washer, Bottle Capper, Conveyor, Bottle Dryer, Bottle Warmer, Bottle Loading system, Bottle unscrambler, CIP system, Bottle Cooler, Bottle Sterilizer, Blending tank, Storage Tank, Sugar Melting Pot, Syrup Filter Conveyor and so on.

RELIABLE will supply you bottle design, label design, workshop design free and make turnkey project equipments for you.

Don't hesitate to contact us if you show interesting on our beverage production machine and our RELIABLE company.

We Warmly Welcome Customers All Over The World To Our Company.If You Have Interests In Our Products,Please Contract With Us FREELY!

ZHANGJIAGANG RELIABLE MACHINERY CO.,LTD