AGLASSTEC Tempering Furnace Machine with Blower Convection & Passing Quenching Tempered Glass Making Machines FY-JZ2040

1.1 Device Structure: The Furnace one side doors are able to opened, 2 set of loading machine with wheel for 2 meter long glass loading.

1.2 Device Specification:

Device outside dimensions: L4700×W2200×H2800 mm

Device inside dimensions: L4400×W1200×H2250 mm

Covers an area of: L9700×W3600×H3700mm

1.3 The Glass Production Specification:

Homogenous Glass The hugest size:4000×2000 mm

Glass Thickness Range:3-19mm

1.4 Product Performance: BS EN14179-1:2005.Comply with the requirments of BS EN14179-1:2005.

1.5 Total Power:140kW(Heating power120KW)

1.6 Voltage:3 Cabins 380V /50HZ.

2 The main technical performance:

The tempering glass heat soak furnaces is made as the Europe standard which is strengthen safety of glasses. Adopting solid state relay. The computer can record and control the parameters intelligently. Temperature control mode is auto completed by electronic control system, which based on PLC and Kingview. The temperature and the result can be record and print automatically each time. The air circulating system is made up by8 blowers.

There are four convection fans on the top , at the same time add Control of cooling by one cooling fan. There are 20 thermocouples in the heat furnace body, can monitor temperature on surface of glasses from every area. 6 thermocouples distributed on the top of the furnace can monitor the air temperature in the furnace.

3 Process parameters:

According to EN14179-1:2005 standards, it can achieve the following temperature and wind cycling by computer logic control

Normal heating temperature(Below 50ºC) to limit requirements temperature (290 ºC ±10 degrees) 60 min-120 min;

Keep the top limit temperature (290 ±10 degrees) 120 min-480 min;;

Temperature to cooling temperature (70 degrees) 120 min--480 min; The maximum temperature is able to adjust

±10ºC Empty furnace :the biggest difference temperature: ±10 degrees;

±10ºC Full furnace temperature: the biggest temperature difference is :±10 degrees;

Constant temperature: normal temperature to 320 degree, can be set in a random;

Constant temperature and time limit alarm temperature can be set in a random;

Attachment One

Heat soak time/temperature rules

To implementation of the equipment acceptance work to achieve EN14179-1:2005.The following requirements for process and control, as below:

1, calibration standard:

Homogeneous system must follow the picture 1. The system must be able to achieve the load of 100% and 10%.

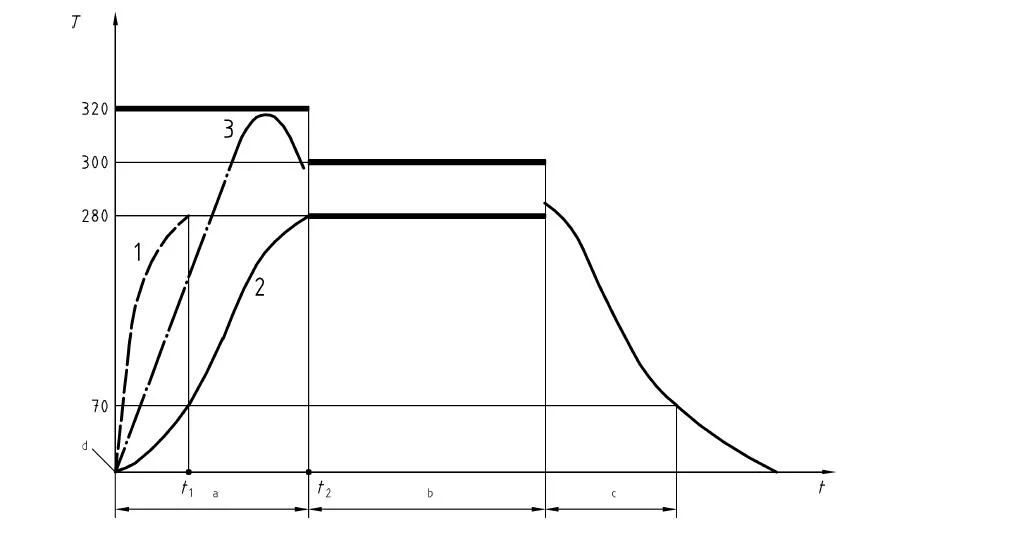

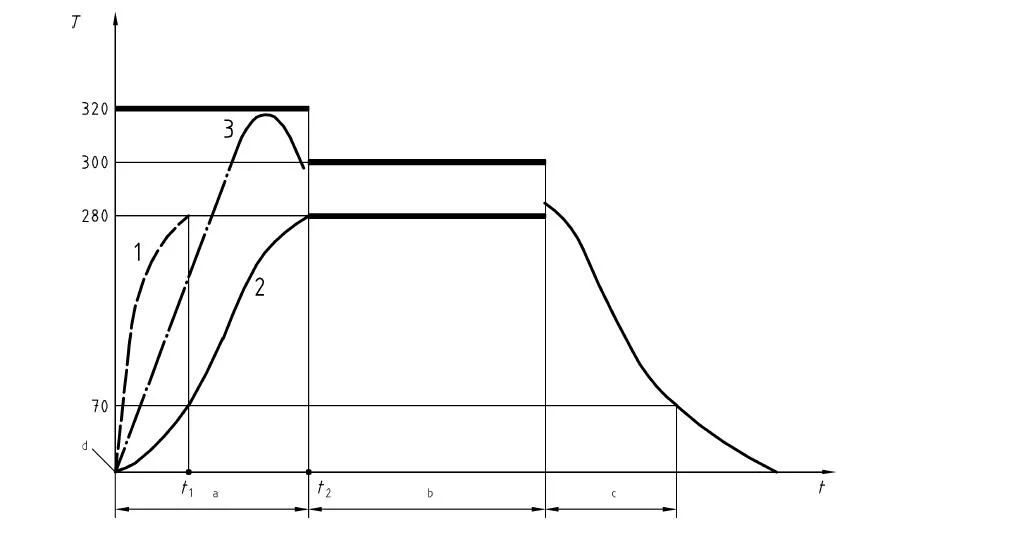

Picture 1 Standard Homogeneous time/Temperature rules

T Any pints of glass temperature.

t Time hour

t1 Time of first piece of glass to 280 ºC

t2 Time of last piece of glass to 280 ºC

1 The first piece of glass temperature to 280 ºC

2 The last piece of glass temperature to 280 ºC

3 Glass temperature

a Heating period

b Constant temperature period

c Cooling period

d Ambient temperature

Note 1: full load depends on the size , the thickness of the glass and furnace volume. General base on 6 mm or 8 mm thickness, the distance between the glass depends on the location, type of glass and interal things shape decision.

Note 2: The minimum distance is 20 mm.

2. the collection of temperature

Inner furnace is no less than 6 points fixed temperature gathering and glass surface is more than 20 point temperature gathering, this some points is under the standards of the EN14179-1:2005 of installation, put, calibration .

Note 1: the furnace and glass surface temperature can be tested in full load .

Note 2: the furnace temperature can control unit monitoring at the air outlet. Glass surface temperature is measured of the hot good contact thermocouple in the glass surface.

3,Test procedure, content

a, At the beginning, the air temperature of inside the furnace should be more than 50 ºC.

b. During the heating, should be heated to the last piece of glass temperature to 280 ºC.

c. During the heating, any glass surface temperature should not exceed 320 ºC.

d. During heating, the following parameters must record automatically:

a. Tc any time the temperature of the monitors

b. t1 Time of first piece of glass to 280 ºC

c. Tc1 monitors time

d. t2 Time of last piece of glass to 280 ºC

e. Tcmax The highest temperature of monitors

f. tcmax The time of the highest temperature

g. Tglass Any time glass surface temperature

U keep period from in the time t2 to two hours. Glass surface temperature is in the range of 290 ºC ±10 ºC. Tc Monitor temperature need to record down.

U cooling section begin in t2 + 2 h Monitor temperature Tc need to record. When Tc to 70 ºC furnace can open .

U Each phase of the time requirements (100% load) : warming period :120min≤a≤480min,can be adjusted continuously; Constant temperature period:60min≤b≤480min , can be adjusted continuously; Cooling period: 60min≤c≤240min, can be adjusted continuously.

Execution Standards : BS EN 14179-1:2005

1. Temperature control mode is Temperature acquisition module, PLC and Kingview, make it more stable.

2. 6 pcs Thermocouple of the furnace ,to detect the furnace temperature

3. 20 pcs Thermocouple to test glass surface , while 34 pcs Thermocouple to show in the interface.

4. Heating area: 8pcs, match 8 groups convection fan.

5. There are four convection fans on the top , at the same time add Control of cooling by one cooling fan

Technology parameters

1.Furnace outer size: L4700*W2200*H2800mm

2.Furnace inner size :L4400*W1200*H2250mm

3.The maxi size of glass :4000*2000mm

4.Thickness of glass: 3-19mm

5.The highest temperature :340 ºC

6.Working temperature: 290 ºC±10 ºC

7.Total power:140KW

8.Heating power:120KW

9.4 sets of forced convection fan on the top( 4 kw/set), large impeller, air volume is larger 1/4 than our competitors

10. one set of cooling fan( 4 kw/set), use cool water cooling system and air cooling cooling system.

11. 8 pcs of cold wind door, open and colse by air cylinder.

12.one side open of the furnace .

13. 2 set of2 meter long A sheet, the bottom plate is weld for broken glass , .

14. Power supply: 380V/50Hz.

15. Source: 0.5-0.7 MPA

16. Weight: 8 T

17. Production capacity:6000 KG/Circle

18. Covers an area of size: length L9700×W3600×H3700mm

FAQ:

Q1: Are you a trading company or a manufactory?

A1: We are a manufactory, we supply the factory price with good quality, welcome to visit !

Q2: Why choosing AGLASSTEC ?

A2: Founder of the company engaged in machinery manufacturing industry almost 20 years of experience, professional production and export of high-quality glass processing machinery, industrial automation machinery, etc. , exported to all parts of the world, we have been committed to doing a good job of products, service every customer.

Q3: Machine warranty specifications ?

A3: We will provide lifelong maintenance service in the use of machinery, we will solve

problems for customers free of charge, eliminate all the troubles of customers. For

machines beyond the warranty period, we will always provide follow-up services and

provide wearing parts for free, but we do not provide freight, local customs clearance fees

and related costs.

Q4: This is the first time I buy glass machine, is it easy to operate?

A4: We can provide the operation manual or video for guiding. If it is hard for you learning, We can help you by "Team viewer" online, with telephone or WhatsApp explain. And We will send our engineers to your factory to install the machines and train your staff how to operate the machines.

Q5: How to choose a suitable machine ?

A5: You can tell us working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience.

Q6: How can I trust your company and your products ?

A6: The whole production procedure will be under regular inspection and strict quality

control. The complete machine will be tested to make sure they can work very well

before being out of factory. The testing video and pictures will be available before

delivery.

Q7: If machine have any problem after I ordered it, what could I do ?

A7: Free parts send to you in machine warranty period if machine have any problem. Free after-sales service life for machine, please feel free contact us if your machine have any problem. We will give you 24hours service from telphone and WhatsApp.

Q8: How about the spare parts?

A8: After we deal down all the things , we will offer you a spare parts list for your reference.

- Technique and Configuration

1.1 Device Structure: The Furnace one side doors are able to opened, 2 set of loading machine with wheel for 2 meter long glass loading.

1.2 Device Specification:

Device outside dimensions: L4700×W2200×H2800 mm

Device inside dimensions: L4400×W1200×H2250 mm

Covers an area of: L9700×W3600×H3700mm

1.3 The Glass Production Specification:

Homogenous Glass The hugest size:4000×2000 mm

Glass Thickness Range:3-19mm

1.4 Product Performance: BS EN14179-1:2005.Comply with the requirments of BS EN14179-1:2005.

1.5 Total Power:140kW(Heating power120KW)

1.6 Voltage:3 Cabins 380V /50HZ.

2 The main technical performance:

The tempering glass heat soak furnaces is made as the Europe standard which is strengthen safety of glasses. Adopting solid state relay. The computer can record and control the parameters intelligently. Temperature control mode is auto completed by electronic control system, which based on PLC and Kingview. The temperature and the result can be record and print automatically each time. The air circulating system is made up by8 blowers.

There are four convection fans on the top , at the same time add Control of cooling by one cooling fan. There are 20 thermocouples in the heat furnace body, can monitor temperature on surface of glasses from every area. 6 thermocouples distributed on the top of the furnace can monitor the air temperature in the furnace.

3 Process parameters:

According to EN14179-1:2005 standards, it can achieve the following temperature and wind cycling by computer logic control

Normal heating temperature(Below 50ºC) to limit requirements temperature (290 ºC ±10 degrees) 60 min-120 min;

Keep the top limit temperature (290 ±10 degrees) 120 min-480 min;;

Temperature to cooling temperature (70 degrees) 120 min--480 min; The maximum temperature is able to adjust

±10ºC Empty furnace :the biggest difference temperature: ±10 degrees;

±10ºC Full furnace temperature: the biggest temperature difference is :±10 degrees;

Constant temperature: normal temperature to 320 degree, can be set in a random;

Constant temperature and time limit alarm temperature can be set in a random;

Attachment One

Heat soak time/temperature rules

To implementation of the equipment acceptance work to achieve EN14179-1:2005.The following requirements for process and control, as below:

1, calibration standard:

Homogeneous system must follow the picture 1. The system must be able to achieve the load of 100% and 10%.

Picture 1 Standard Homogeneous time/Temperature rules

T Any pints of glass temperature.

t Time hour

t1 Time of first piece of glass to 280 ºC

t2 Time of last piece of glass to 280 ºC

1 The first piece of glass temperature to 280 ºC

2 The last piece of glass temperature to 280 ºC

3 Glass temperature

a Heating period

b Constant temperature period

c Cooling period

d Ambient temperature

Note 1: full load depends on the size , the thickness of the glass and furnace volume. General base on 6 mm or 8 mm thickness, the distance between the glass depends on the location, type of glass and interal things shape decision.

Note 2: The minimum distance is 20 mm.

2. the collection of temperature

Inner furnace is no less than 6 points fixed temperature gathering and glass surface is more than 20 point temperature gathering, this some points is under the standards of the EN14179-1:2005 of installation, put, calibration .

Note 1: the furnace and glass surface temperature can be tested in full load .

Note 2: the furnace temperature can control unit monitoring at the air outlet. Glass surface temperature is measured of the hot good contact thermocouple in the glass surface.

3,Test procedure, content

a, At the beginning, the air temperature of inside the furnace should be more than 50 ºC.

b. During the heating, should be heated to the last piece of glass temperature to 280 ºC.

c. During the heating, any glass surface temperature should not exceed 320 ºC.

d. During heating, the following parameters must record automatically:

a. Tc any time the temperature of the monitors

b. t1 Time of first piece of glass to 280 ºC

c. Tc1 monitors time

d. t2 Time of last piece of glass to 280 ºC

e. Tcmax The highest temperature of monitors

f. tcmax The time of the highest temperature

g. Tglass Any time glass surface temperature

U keep period from in the time t2 to two hours. Glass surface temperature is in the range of 290 ºC ±10 ºC. Tc Monitor temperature need to record down.

U cooling section begin in t2 + 2 h Monitor temperature Tc need to record. When Tc to 70 ºC furnace can open .

U Each phase of the time requirements (100% load) : warming period :120min≤a≤480min,can be adjusted continuously; Constant temperature period:60min≤b≤480min , can be adjusted continuously; Cooling period: 60min≤c≤240min, can be adjusted continuously.

Execution Standards : BS EN 14179-1:2005

1. Temperature control mode is Temperature acquisition module, PLC and Kingview, make it more stable.

2. 6 pcs Thermocouple of the furnace ,to detect the furnace temperature

3. 20 pcs Thermocouple to test glass surface , while 34 pcs Thermocouple to show in the interface.

4. Heating area: 8pcs, match 8 groups convection fan.

5. There are four convection fans on the top , at the same time add Control of cooling by one cooling fan

Technology parameters

1.Furnace outer size: L4700*W2200*H2800mm

2.Furnace inner size :L4400*W1200*H2250mm

3.The maxi size of glass :4000*2000mm

4.Thickness of glass: 3-19mm

5.The highest temperature :340 ºC

6.Working temperature: 290 ºC±10 ºC

7.Total power:140KW

8.Heating power:120KW

9.4 sets of forced convection fan on the top( 4 kw/set), large impeller, air volume is larger 1/4 than our competitors

10. one set of cooling fan( 4 kw/set), use cool water cooling system and air cooling cooling system.

11. 8 pcs of cold wind door, open and colse by air cylinder.

12.one side open of the furnace .

13. 2 set of2 meter long A sheet, the bottom plate is weld for broken glass , .

14. Power supply: 380V/50Hz.

15. Source: 0.5-0.7 MPA

16. Weight: 8 T

17. Production capacity:6000 KG/Circle

18. Covers an area of size: length L9700×W3600×H3700mm

Glass tempering furnaces are designed to make finished pieces of glass both stronger and safer in the event that they break. Glass tempering furnaces heat up a piece of glass to a very high temperature, usually over 600° Celsius, and then rapidly cool it uniformly using air jets, a process called quenching. The rapid cooling causing the surface of the glass to undergo extreme compression, making it much stronger against impacts and heat shock. Additionally, due to the intense pressures within the glass, if the glass fails, it shatters into several tiny and relatively spherical pieces, making it much less likely for people to become injured from the shards.

Scope of supply and configuration:| Glass homogenizer (hot-dip) furnace FY-JZ4020 main configuration list | ||||

| Name | Pecification | Qty | Brand | Note |

| Furnace Steel pipe | 60*80 | Chinese Standard | ||

| Furnace door's pipe | 50*100 | Chinese Standard | ||

| Steel pipes of the glass loading trolley | 80*80 40*40 | Chinese Standard | ||

| Furnace Cold Plate | Chinese Standard | |||

| Furnace Hot Plate | Chinese Standard | |||

| Furnace Interior | Stainless steel plate | Chinese Standard | ||

| Furnace duct interiors | Galvanized sheet | Chinese Standard | ||

| Punching guard outside the furnace | Cold Plate | Chinese Standard | ||

| Glass loading trolley rolling axis | 60mm diameter round | 8 pcs | Chinese Standard | |

| The Bearing of the Glass loading trolley | High temperature ball bearings | 16 pcs | Chinese Standard | |

| Convection blower | 4Kw | 4sets | china | |

| Cooling blower | 4Kw | 1set | china | |

| PLC | 1 pc | MITSUBISHI | ||

| PLC Expand | 2 pcs | MITSUBISHI/SIEMENS | ||

| inverter | 1 pc | MITSUBISHI/bosch | ||

| Solid-state relay SSR | 24 pcs | Schneider | ||

| Fuse | 24pcs | Schneider | ||

| The main computer | 1pc | Hp | ||

| Screens | 1pc | TaiwanAOC | ||

| Electric | Master Device | SCHNEIDER | ||

| Temperature acquisition module | 4pcs | Mingyang of Taiwan | ||

| Temperature control software | 1set | Beijing kingview | ||

| Heating tube | Stainless steel flake type | Chinese Brand | ||

| Cylinder | Chinese Brand | |||

| Solenoid valve | Chinese Brand | |||

| Track | 12# rail steel | Chinese Brand | ||

| Glass Spacer | Isolated glass width 20mm | Several | Chinese Brand |

FAQ:

Q1: Are you a trading company or a manufactory?

A1: We are a manufactory, we supply the factory price with good quality, welcome to visit !

Q2: Why choosing AGLASSTEC ?

A2: Founder of the company engaged in machinery manufacturing industry almost 20 years of experience, professional production and export of high-quality glass processing machinery, industrial automation machinery, etc. , exported to all parts of the world, we have been committed to doing a good job of products, service every customer.

Q3: Machine warranty specifications ?

A3: We will provide lifelong maintenance service in the use of machinery, we will solve

problems for customers free of charge, eliminate all the troubles of customers. For

machines beyond the warranty period, we will always provide follow-up services and

provide wearing parts for free, but we do not provide freight, local customs clearance fees

and related costs.

Q4: This is the first time I buy glass machine, is it easy to operate?

A4: We can provide the operation manual or video for guiding. If it is hard for you learning, We can help you by "Team viewer" online, with telephone or WhatsApp explain. And We will send our engineers to your factory to install the machines and train your staff how to operate the machines.

Q5: How to choose a suitable machine ?

A5: You can tell us working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience.

Q6: How can I trust your company and your products ?

A6: The whole production procedure will be under regular inspection and strict quality

control. The complete machine will be tested to make sure they can work very well

before being out of factory. The testing video and pictures will be available before

delivery.

Q7: If machine have any problem after I ordered it, what could I do ?

A7: Free parts send to you in machine warranty period if machine have any problem. Free after-sales service life for machine, please feel free contact us if your machine have any problem. We will give you 24hours service from telphone and WhatsApp.

Q8: How about the spare parts?

A8: After we deal down all the things , we will offer you a spare parts list for your reference.